Understanding Rapid Tooling Service

Rapid tooling service is a game-changer in the manufacturing sector. It’s all about speed and efficiency. Gone are the days when it took months to develop a mold for a prototype. With rapid tooling, designs can be transformed into tangible products in a fraction of the time. This means that if you’re a small business or a large manufacturer, you can get your products to market faster than ever. Think about it: you come up with an idea, and within weeks, you can see it come to life. This level of agility in manufacturing can set you apart from your competitors.

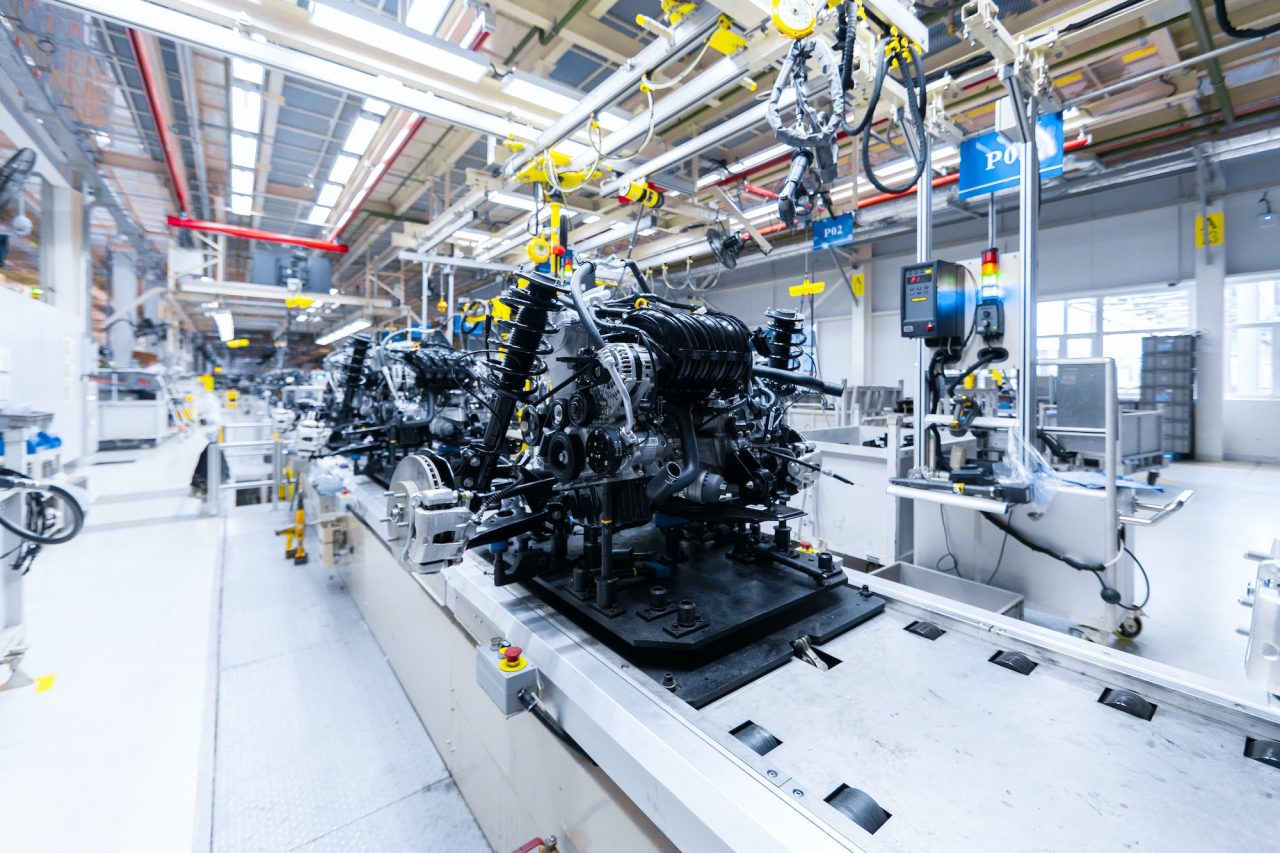

Real-World Applications

Let’s dive into real-world applications of rapid tooling service. Imagine you’re a company designing the next big consumer gadget. With traditional tooling, the journey from concept to prototype could take months or even years. But with a rapid production tooling service, you could create prototypes in days. This lets you test your ideas quickly and iterate based on feedback. Industries like automotive and consumer electronics are already reaping the benefits. They can test multiple designs without breaking the bank, allowing for innovation without the typical constraints of slow production times.

Advantages of Rapid Production Tooling Service

This rapid production tooling service brings plenty of advantages. First off, the speed allows companies to significantly shorten their development cycles. This is crucial in industries where timing is everything. You can launch products faster, which translates to faster revenue generation. Additionally, the service reduces costs associated with traditional tooling methods. By getting it right the first time, you minimize the need for costly revisions down the road. Also, the flexibility offered lets businesses pivot their prototypes based on real-time market feedback, making the whole process more efficient and user-centered.

Emphasizing Practicality in Rapid Production Tooling Service

In today’s fast-paced world, every second counts. That’s where a rapid production tooling service comes into play. It’s not just about speed; it’s also about maintaining quality. With advancements in technology, prototypes not only come out quicker but are also crafted with precision. You can mitigate risks by testing prototypes under actual production conditions, ensuring that the final product is ready for market. Plus, by integrating customer feedback early in the development process, you align your offering with market needs, enhancing your product’s acceptance once it’s launched. This process promotes a more reliable, user-focused manufacturing strategy.

Conclusion: Choose APT-Mold for Your Rapid Tooling Needs

To wrap it all up, the benefits of rapid tooling service are crystal clear. If you’re looking to optimize your manufacturing processes and enhance your product development speed, consider leveraging the expertise of APT-Mold. They specialize in providing robust manufacturing solutions with significant supply advantages, ensuring you get your product to market faster without compromising on quality. With APT-Mold, you can tackle your production challenges head-on and embrace innovation like never before.